Bioreactors - The heartbeat of Biopharmaceutical Manufacturing For many biopharmaceutical manufacturing companies, the bioreactor is…

What are the 5 main steps of CIP?

What does CIP mean?

CIP stands for Cleaning in Place.

In the biopharmaceutical manufacturing industry, most vessels such as bioreactors are cleaned without being dismantled. Special cleaning solutions are used to remove any residue left after the bioreactor has been used.

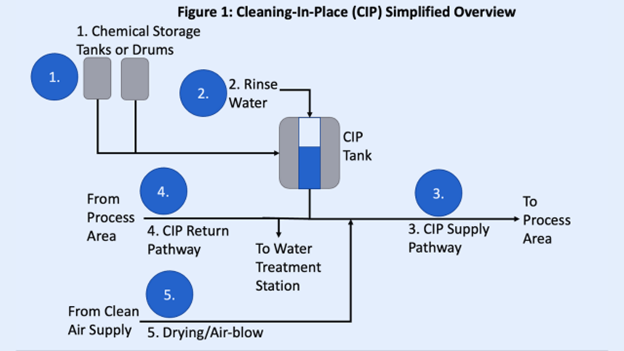

There are 5 main steps involved in the CIP process as shown in Figure 1 below:

- Cleaning Chemicals

- Rinse Water

- CIP Supply Pathway

- CIP Return Pathway

- Drying/Airblow

Let’s look at each step in more detail.

1. Find out who makes it

Storage vessels or 55-gallon drums are typically used to store CIP cleaning chemicals. The most commonly used types of chemicals are:

- Caustic (sodium hydroxide)

- Acid (phosphoric acid)

2. Rinse Water

Rinse water is used to flush out the chemicals used during the CIP process.

This water is typically generated from Reverse Osmosis skids.

3. CIP Supply Pathway

It’s important to develop a process pathway that allows the cleaning solution and rinse water adequate surface area during CIP.

Any residue left behind will result in contamination.

4. CIP Return Pathway

Gravity draining or forced draining using a pump ensures all visible moisture is removed and returned to the CIP skid.

5. Drying/Air Blow

Perhaps the most critical CIP step is thoroughly drying the CIP pathways using pressurized clean air.

Note: Ensure any manual isolation valves in the process air lines are turned ON as shown in the image below.

For more tips and to learn how to reduce equipment downtime and boost production by digitalizing your equipment data, reach out to use today at contact@quneup.com or 267-207-3953.